- info@kblbinvestors.com

Kraig Biocraft Laboratories, (KBLB) Inc. is a fully reporting biotechnology company on the OTCQB focused on the development and commercialization of new textiles and high performance fibers including spider silks. As a reporting company, our annual and quarterly reports to the SEC can be found on EDGAR and on this website. Our investments in genetic research are targeted for product development and innovative near-term solutions to meet the practical problems of our world.

WATCH OUR PRESS CONFERENCES BELOW

How our breakthrough technology works!

BEFORE YOU INVEST IN KBLB

Learn More About Kraig Biocraft Labs

Kraig Biocraft Labs has crafted a once-in-a-lifetime technology, raising the performance bar with custom recombinant spider silk fibers and polymers. This new technology could displace current industry technologies and standards for advanced technical textiles and various other protective materials.

Kraig Labs was born out the necessity to produce improved fibers and polymers. We are dedicated to producing the best technologies both for our investors and end-users. Our target markets include military, police and DHS related applications; athletic wear, other industrial and consumer applications, clothing and fashion wear; and significant existing silk product markets.

Mother Nature played a hand in making spider silk the super fiber that it is. At Kraig Biocraft Laboratories we plan on improving products, and then lives, by producing it in commercial quantities.

LATEST PRESS RELEASES

Kraig Biocraft Laboratories

Kraig Biocraft Laboratories

- Kraig Biocraft Laboratories Targets New Industrial and Defense Biomaterials as “Project Atlas” Hits Major Milestone March 5, 2026

- Kraig Biocraft Laboratories’ Spider Silk Advancements Featured as the Cover of National Geographic’s March 2026 Issue February 23, 2026

- Kraig Biocraft Laboratories Activates First Wave of 2026 Production Program February 17, 2026

- Kraig Biocraft Laboratories Poised for Explosive Spider Silk Production Growth February 9, 2026

- Kraig Biocraft Laboratories Rings in the New Year with the Most Ambitious Genetic Engineering Program in its History January 20, 2026

MILESTONES & MARKETS

Step into the future of fiber technology, one milestone at a time.

Promises made. Promises kept. KBLB meets milestones that matter for stakeholders

July 12, 2016 – Kraig Labs receives a contract, valued at up to $1.0 million, if the option phase is awarded, for the development of high performance fibers for protective apparel applications. Under the fully funded base effort, valued at $99,962, the Company will deliver ballistic shoot packs constructed from its proprietary Dragon Silk™ material for performance testing.

The government contract and the accompanying production capacity increase caught the attention of international media and were covered by numerous leading media outlets.

Add Your Tooltip Text Here

*Companies past milestone and performance is not indicative of future results

Add Your Tooltip Text Here

*Companies past milestone and performance is not indicative of future results

December 19, 2016 – Kraig Labs completed the first batch of Dragon Silk™ cocoon production for its military contract. The fibers will soon be headed to a reeling facility to be prepared for delivery to Warwick Mills.

The Company will contract Warwick Mills to produce ballistic shoot packs, for delivery to the US Army, based on the Company’s Dragon Silk technology. The Company expected to make final delivery to the US Army in the second quarter of 2017.

March 27, 2017 – Kraig Labs was awarded an Investment Certificate for the production of high technology silk in Vietnam’s Quang Nam province, during the March 26, 2017 Quang Nam Investment Conference, which was attended by Vietnam’s Prime Minister and numerous high level central government officials, including the ministers of all relevant governmental departments, as well as high level officials from Quang Nam province, including the Chairman and key provincial officials. Representing Kraig Labs at the meeting were the Company’s CEO and Founder, Kim Thompson, and COO, Jon Rice.

Add Your Tooltip Text Here

*Companies past milestone and performance is not indicative of future results

Add Your Tooltip Text Here

*Companies past milestone and performance is not indicative of future results

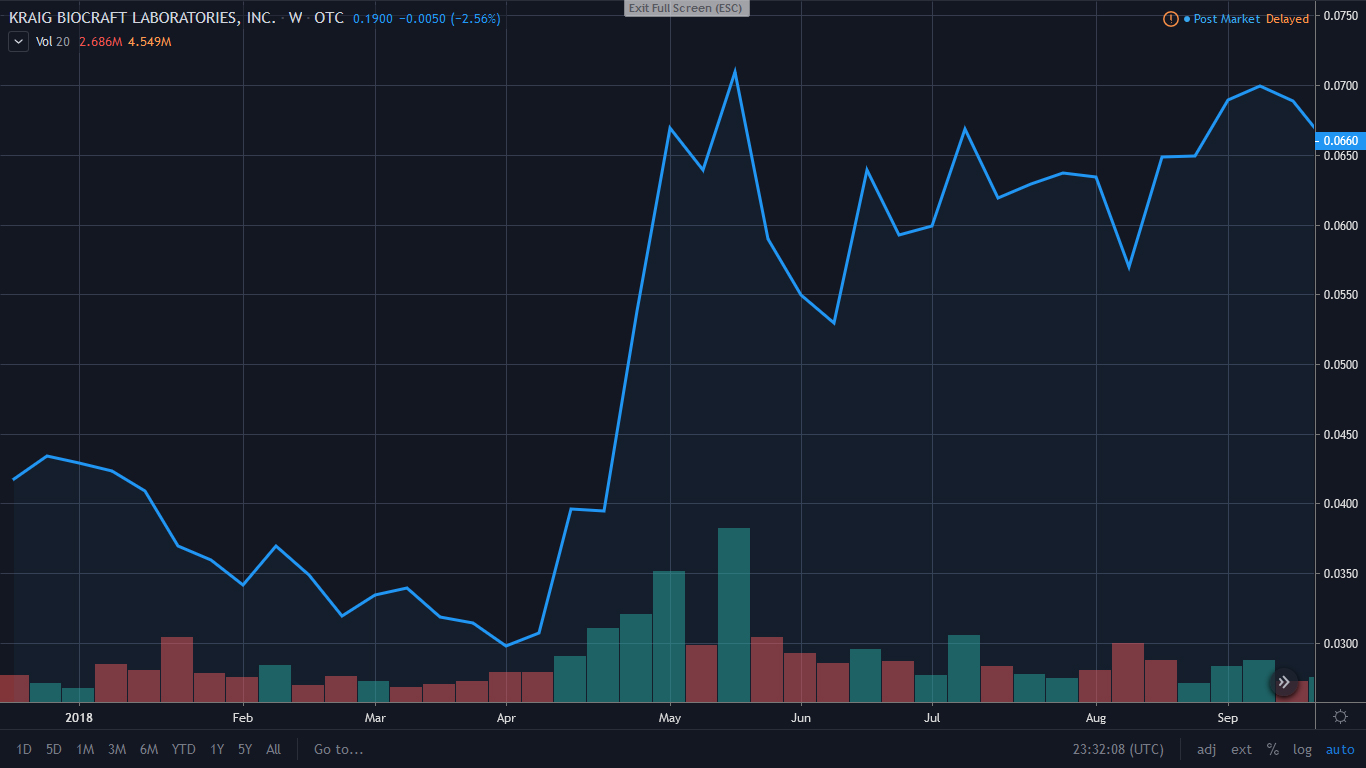

May 1, 2018 – As the result of five years of working with the Vietnamese government, at the national and provincial levels, Kraig Labs was issued its long awaited Enterprise Registration Certificate (ERC), which is required to begin its operations in Vietnam.

“Our work to obtain these approvals has been driven by our goal of producing recombinant spider silk on a large scale, which can only be achieved by harnessing the opportunities presented by existing large scale silk production infrastructure,” stated Kim Thompson, CEO, in reference to the Company’s advanced silk production platform, which was designed specifically to fit within and utilize existing silk industry infrastructure.

April 17, 2019 – Polartec, the premium provider of innovative and sustainable textile solutions, and Kraig Biocraft Laboratories (Kraig) (OTC:KBLB), the biotechnology company focused on the development and commercialization of spider silk, announce plans to bring to market the first fabrics made from spider silk. Initially developed for specialized military applications, these first-of-their-kind materials made from recombinant spider silk will eventually service the global market for high performance textiles and apparel.

Add Your Tooltip Text Here

*Companies past milestone and performance is not indicative of future results

BECOME A STAKEHOLDER

Invest In Our Future

HISTORY IN THE MAKING

Kraig Biocraft's Timeline

Using the laboratory to turn a great idea into advanced spider silk fiber reality

HISTORY IN THE MAKING

The advantages of Spider Silk

Unequalled combination of elasticity and tensile strength represents technological paradigm shift.

Genetically engineered spider silk fibers have uses in various applications and markets.

Biodegradable and biocompatible.

Spider silk production could greatly reduce many of the toxins and pollutants used in conventional petroleum based fiber and polymer production process.

Collaborations with well-respected institutions, such as the University of Notre Dame, has accelerated and enabled a number of exciting breakthroughs in the laboratory. We are very thankful for the media coverage we receive, which helps us spread the word about recombinant spider silk, along with the Publication of the National Academy of Sciences (PNAS) peer-reviewed journal, which credibly confirms our proof-of-concept.

WE BEAT THE COMPETITION

Why our technology is the best

THE PEOPLE BEHIND KRAIG LABS

Kraig Biocraft's Executive Team

The Company has assembled a team of leading biotechnology experts, and others with experience spanning critical areas of science and business.

Table goes here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Thinking of investing in KBLB?

Get The Latest KBLB Updates

Stay Updated with Kraig’s Developments

IT'S 100% FREE TO START RECEIVING OUR ALERTS!

Kraig Biocraft Laboratories, Inc.

-

2723 South State Street Suite 150

Ann Arbor, Michigan 48104 - www.KraigLabs.com

- corporate@KraigLabs.com

Navigate

Latest Press Releases

Latest Press Releases

- Kraig Biocraft Laboratories Targets New Industrial and Defense Biomaterials as “Project Atlas” Hits Major Milestone March 5, 2026

- Kraig Biocraft Laboratories’ Spider Silk Advancements Featured as the Cover of National Geographic’s March 2026 Issue February 23, 2026

- Kraig Biocraft Laboratories Activates First Wave of 2026 Production Program February 17, 2026